Pre-trip inspections are more than just cursory searches for mechanical defects. They’re required by law, and failing to do them can cost your company dearly. Perhaps equally important, these inspections can save lives, help your vehicles last longer, and ultimately help you make more money — and keep more of what you earn rather than paying fines or lawsuits.

The problem, of course, is that it’s easy for pre-trip inspections to become just one more thing you do by mindlessly. Rather than inspecting the vehicle to ensure it’s truly safe to operate, drivers or inspectors may just run through a list, quickly checking boxes without really paying attention to potential problems.

That’s a choice that puts everyone on the road in danger. So it’s time to refocus on your pre-trip inspections, and ensure they truly protect your drivers, your vehicles, and the public.

Don’t forget about these 5 often-overlooked issues during a pre-trip inspection.

SAFETY IN THE CAB

Safety begins in the cab of the truck. Many drivers spend long days on the road, and the truck cab becomes part home, part hotel, part garbage heap. That results in a cab chock full of old food, magazines, garbage, clothes, and an embarrassing cornucopia of other sundry items. These items are more than just an eyesore. They’re also a safety issue.

Consider how a driver fumbling for his wallet might knock a ton of other items loose, or take his eyes off of the road. Or how a driver who’s allowed too many bags of Cheetos to accumulate in her cab might accidentally knock trash under the brakes.

If there is an accident, trash in the cab can fly into the driver and injure them. It can crack windshields. If the windows are down, it can even fly out of the cab. A driver going 55 mph or more turns those small items into dangerous projectiles.

Don’t forget that cleanliness counts when it comes to driving. Check the cab for hidden hazards, and enact strategies to help drivers keep the cab safely clean.

Some other safety issues to check in the cab include:

-

Seatbelt safety. Seatbelts save lives. It’s a cliché because it’s true. So check for signs of dangerous wear and tear, including frayed edges and belts that don’t properly retract. Buckle the seatbelt to ensure it buckles and releases properly. Then give it a sharp tug to ensure it will lock in the event of a crash.

-

Emergency kit. The law requires you to carry an emergency kit, and carrying one can save lives in the event of an emergency. Check for a fire extinguisher, warning hazard triangles, and spare circuit breakers and fuses. If other drivers drive the vehicle, ensure these are all in a central location, and organized in a manner that makes everything easy to find. Don’t just check for the presence of an emergency kit. Make sure everything is in it. And always check to ensure the fire extinguisher actually works.

-

Unusual wear and tear in the cab. Is anything cracked inside of the cab? How do the gears look? Damage to mechanical parts in the cab can point to a more serious problem, so make sure the inside of the cab points to a truck in excellent working order.

WHEEL INSPECTIONS

It’s all about the wheels, as any driver who’s dealt with a flat tire or a damaged axle knows. So don’t just give the wheels a quick once-over. Wheel and tire inspections save lives. One item that may be overlooked is the need to inspect for items lodged between tires.

The Commercial Vehicle Safety alliance recently changed its policies to denote that a solid object lodged between tires is grounds for a violation. At least one driver recently died when a rock hidden here became dislodged and turned into a dangerous projectile. It doesn’t matter how small the stuck item is. If it goes flying at 55 or 70 mph, it can become deadly.

While it’s not legally required, going above and beyond with tire inspections is a great way to prevent damage to vehicles. Consider carefully checking underneath the truck for items that are lodged underneath the vehicle. These could get stuck in tires.

Some other items to pay careful attention to include:

-

Wheel lug nuts. Lug nuts are their own world, with myriad things that can go wrong. One common problem is a weak wheel fastener. This might seem trivial, but a wheel that becomes dislodged and goes barreling down the road is a crisis for the driver, for other motorists, and for your business. It’s so easy to prevent.

-

Rust. Rust around lug nuts may point to a problem with the bolt hole. Check for severely rusty areas around the wheels as well, since these areas can become weakened and misshapen with time.

And of course, don’t forget to chock the wheels at the beginning of the inspection. It seems obvious. It seems silly even to mention it. But when you do hundreds of inspections at year, it’s easy to forget these important basics. Your engine will be running, and the truck can move. Prevent a potential disaster by ensuring the vehicle is stabilized.

BRAKE CHECKS

Trucks depend on their brakes. Other drivers depend on these brakes not to fail. And let’s face it: when truckers are rushing to get from point A to point B, some test their brakes a lot more than they should. They drive to fast, follow too closely, or are too slow to stop.

So brake inspections should operate according to the assumption that the brakes need to work perfectly. Don’t assume that a driver will compensate for faulty brakes, or that OK brakes are good enough. Failed brakes kill. Drivers and operators intuitively know this, but many continue to gloss over brake checks. Don’t be one of them.

Brake violations are a leading cause of road accidents, a primary source of mechanical failures, and among the most common roadside inspection violations. Brake checks involve many steps, both inside and outside of the cab. Don’t neglect any step, since a simple inspection can reveal a potentially life-threatening brake issue.

LIGHTS AND REFLECTORS

With so many lights on a truck, it’s common for one or more to burn out. The violation might seem like a small one, but it’s still a violation — and an easily fixed one, at that. Check each light, and replace any that have burned out or broken. Remember that other drivers depend on these lights to see truckers coming, and that even a few missing lights can make the vehicle less visible.

Don’t forget about reflectors. A quick inspection of your reflectors can reveal easily remedied problems.

PLANNING FOR FUTURE MAINTENANCE

A pre-trip inspection shroud involve more than checking boxes to comply with the law. Ultimately, these inspections are about keeping everyone safe. They’re also a powerful opportunity for you to plan for potential hiccups down the road.

Is a vehicle approaching an oil change?

Might it need new tires in the next 5,000 miles?

Use your pre-trip inspections as a chance to monitor for vehicles that are still in good working order, but that might need maintenance in the next several months. This allows you to budget for necessary maintenance, change your trip schedule as necessary, and ensure the vehicle is assigned to a mechanic well before it passes the deadline for routine maintenance.

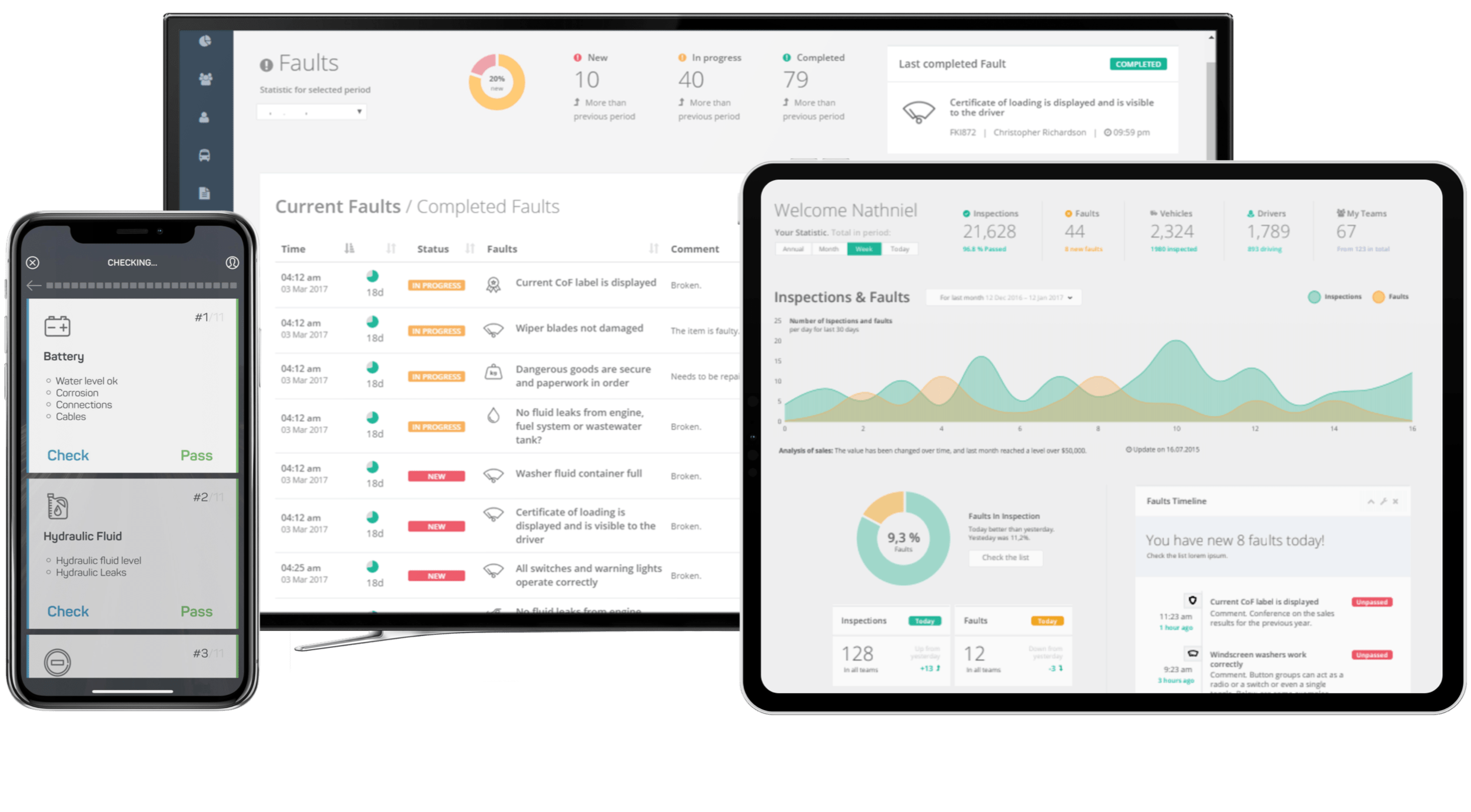

Having a system already in place for flagging vehicles that may need maintenance can save you time, hassle, and stress. Whip Around allows you to build your own inspection forms, then assign vehicle maintenance to the mechanic of your choice. Consider incorporating form details that allow drivers to flag that a vehicle may soon need maintenance. It’s a simple way to keep your schedule, and your sanity, intact.

HOW WHIP AROUND MAKES INSPECTIONS SAFER AND EASIER

Let’s face it: pre-trip inspections take time. They also create their own set of problems, including:

-

The need to pull vehicles from the road to schedule them for routine maintenance.

-

Monitoring the progress of major repairs to damaged vehicles.

-

Keeping track of and storing inspection reports.

-

Ensuring drivers fully inspect each vehicle, rather than just ticking off a bunch of boxes.

-

Logging inspection-related data over time. Tracking inspection reports can help you detect problems with specific vehicles or families of vehicles. This can inform buying decisions, help you devise a better inspection timetable, and more.

These inspections are vital for road safety. They’re also critical for the success of your business. Inadequate or missing inspections may:

-

Subject you to costly fines and penalties.

-

Make you more vulnerable to lawsuits, particularly if the other side can show you didn’t do an inspection, or that you ignored the results of an inspection.

-

Delay vehicles from going back on the road. If you miss inspections, this can cause mechanical problems to get worse. That means more time off the road, and more costly repairs.

-

Endanger your drivers and other motorists.

-

Cause you to lose your best drivers, who may go to companies that are better at staying on top of vehicle safety and maintenance.

We understand that pre-trip inspections and DVIRs can be an immense burden. Here are our tips for lightening the load:

FOSTER A SAFETY-FIRST CULTURE

No form or program will fix a culture that prioritizes speed at the expense of safety. The key to effective inspections and safe drivers is a culture that truly prioritizes safety.

Some tips for building that culture include:

-

Not rushing drivers or encouraging them to cut corners.

-

Regular substantive safety training.

-

An open door policy that encourages drivers to express concerns and offer safety strategies.

-

Modeling the behavior you want to see. Emphasize safety in all that you do.

-

Making pre-trip inspections easy for drivers. Build intuitive forms written in plain language. Whip Around lets you do precisely that.

SWITCH TO DIGITAL DVIR REPORTS

Digital DVIR reports alleviate much of the burden posed by pre-trip inspections. The law don’t require you to use any specific form, as long as you address all of the required basic components of an inspection. So build your own. This allows you to ensure your forms make sense, that they are intuitive, and that they force drivers to do a full inspection — not a cursory walk-through.

Whip Around allows you to build elegant functional inspection forms in just minutes. Forget about forms you found online that are irrelevant or nonfunctional. We can show you a better way.

DITCH THE PAPER PILE

Pre-trip inspection forms exist for a reason. They serve as proof of your compliance with the law. And they help you document the entire history of a vehicle. If you are sued, accused of noncompliance, or simply need to review what work you’ve had done to a vehicle, these reports are invaluable.

Yet most managers allow these forms to pile up in a precarious heap in their offices. When they need the forms, they can’t find them. In many ways, they might as well not have them at all. The switch to digital can prevent this hassle. Whip Around allows you to organize forms for each vehicle without a paper pile or a boatload of frustration. If you need information about a specific vehicle, you can search for it without creating an avalanche of paperwork.

Paper can be a hassle for vehicle inspectors, too. They have to find the right form, take it to the inspection, ensure the form isn’t dirty or lost, and then give it to the right person. This is a recipe for missing, damaged, or incomplete paperwork. It’s also a surefire way to frustrate and annoy drivers. At Whip Around, we believe everyone deserves better than this. And we aim to deliver on that belief with solutions that work for today’s fleets.

DON’T RUSH

The number one reason pre-trip inspections fail is that they are rushed. Drivers feel pressured to get on the road so they can earn more money. Managers penalize inspectors who take too long. Or the confusing nature of forms pressures drivers to rush, or to divert their attention to the form instead of the vehicle.

Whip Around can solve all of this, and more. We offer intuitive, customized fleet management services that make pre-trip inspections a snap. Better still, we don’t forget about safety. We can help you save time, money, and hassle while making your inspections more comprehensive. Then we’ll help you flag defects, assign repairs to a mechanic, and get your vehicle back on the road — all with the click of a button.